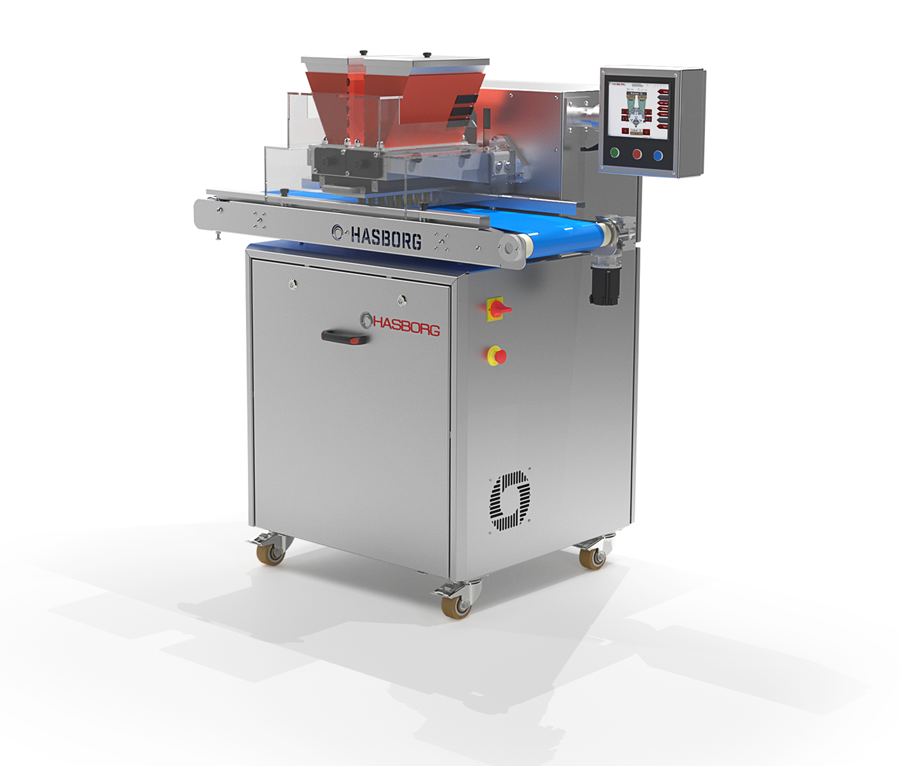

Chocolate enrober can work independently or as one of the elements in full technological line for real chocolate products.

Thanks to the "flow" design, the device allows you to maintain constant tempering parameters without time limits, so that the enrobing process can be continuous and effective. The use of two coating curtains has a positive effect on the quality of the finished product, ensuring a smooth and uniform coating.

Our enrobing machine allows the product to be completely covered, either only from the top or only from the bottom. It is equipped with an efficient function of "blowing system" of excess chocolate and vibration of the transporting mesh, thanks to which we obtain a smooth surface. The heated table has a positive effect on the speed of recovering unused chocolate in the process of enrobing, which returns to the tank where it is subjected to another tempering process, and from there goes again to the working tank. Proper insulation of the working elements also allows the circulation of heated air throughout the coating process, which is important for the quality of the final coating.

The design of the machine facilitates the washing and sanitation process of the device, which saves time and improves work efficiency

Enrober HCM can work directly with cooling tunel HCT

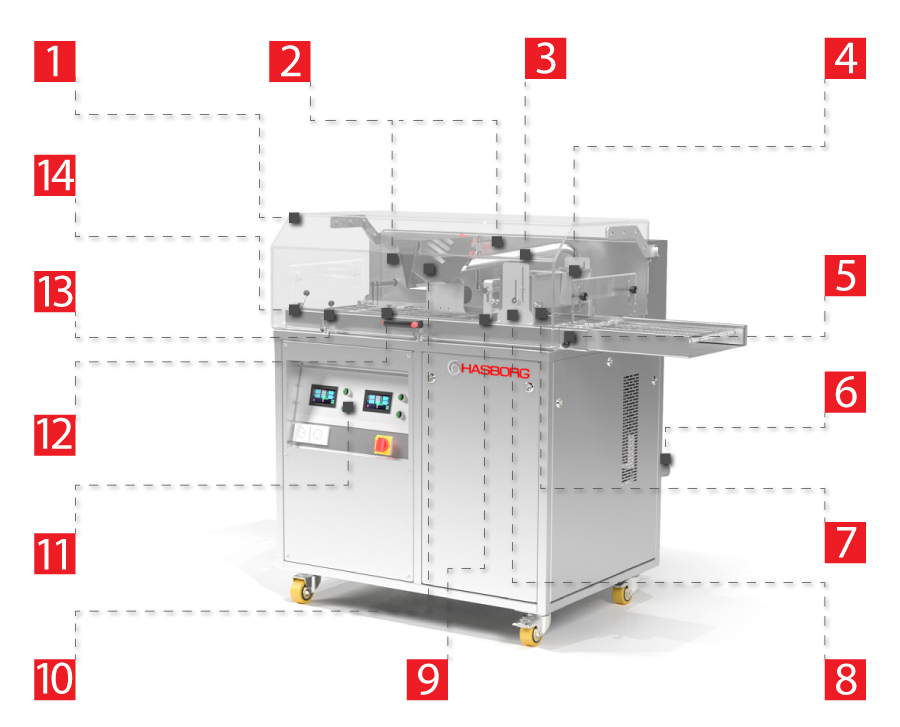

- Insulating cover to maintain stable temperature during the enrobing process

- Warm air supply to the machine working area

- Independent nozzle for production of chocolate praline in manual mode

- Two independent enrobing curtains

- A two-piece conveyor, one of its parts can be detached from the drive

- Drain valve for emptying the tank

- Smooth regulation of chocolote curtain's width

- Smooth regulation of the chocolate flow speed

- Adjustable chocolate level of bottom enrobing

- Air blow system with adjustable power to remove excessive coverage from the top of product.

- Control panel with safety cover to prevent dirt from getting inside

- Adjustable wire-mesh vibration (shaking device)

- system for cleaning the roller from chocolate excess

- Adjustable position and speed of the detailer shaft at the outfeed of the machine

- continuous work

- smooth regulation of wire-mesh conveyor speed

- Top, bottom and entire enrobing

- Fully automatic control of tempering process

- electric heating system

- small size, stable structure

- the possibility of refilling the couverture in small portions while the device is in operation (continuous work)

- small power consumption

- single-phase power supply

- compact size, machine on wheels and low weight make the enrober mobile and easy to use even in a very limited space

- motors and gears

- control system: MKS Stereungstechnik

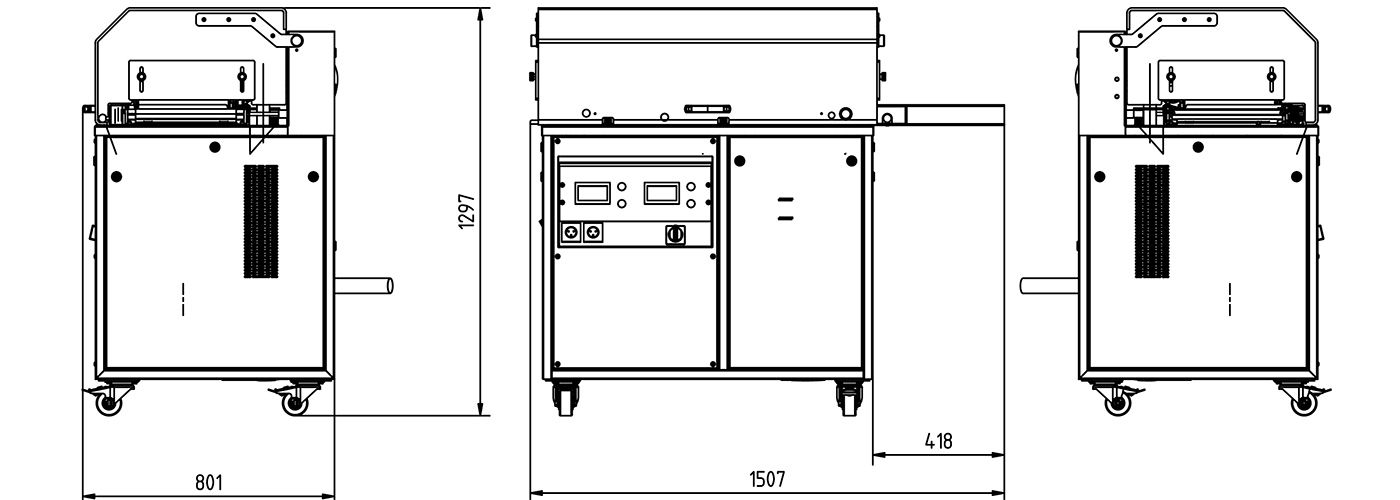

Technical parameters of enrober HCM:

Enrobing of entire product

Top and botton enrobing function makes the product fully covered with coating medium.

Bottom enrobing

The bottom enrobin function is to cover the underside of the product with coating unit. The product transported on the mesh conveyor "flows" over the molten coating. Enrobing height is precisely adjusted depending on the needs.

Romoving of coating medium excess

A product-oriented air stream allows you to easily remove excess coating, so the coating layer on the product is not too thick. Thanks to this function, we can also get effective "waves" on the top of product.

Wire-mesh vibration (shaking system)

The mesh conveyor is equipped with a shaking system, which gives you a possibility to wire-mesh vibration and accelerate the flow of coating from the bottom side of product.

Tempering

The machine can also work as an ordinary tempering machine. After removing the mesh conveyor and the enrobing module - we get a tempering machine, which can be used to fill manually ready-made forms / moulds.

- working width: 320 mm / 240 mm

- size:

lenght: 1507 mm

widtgh: 801 mm

Height: 1297 mm

- installed power:……..kW

- enrobing capacity:….kW