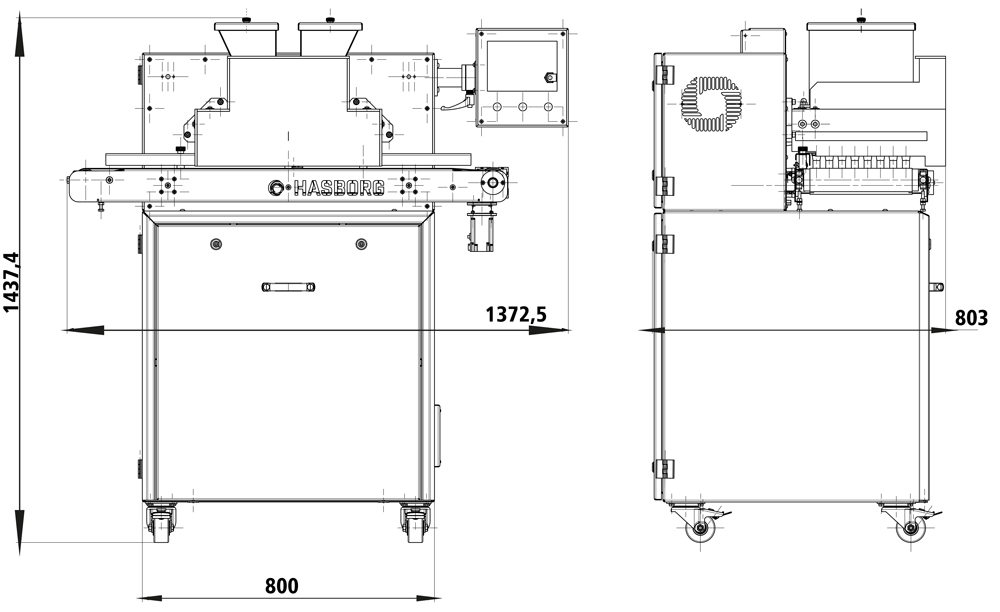

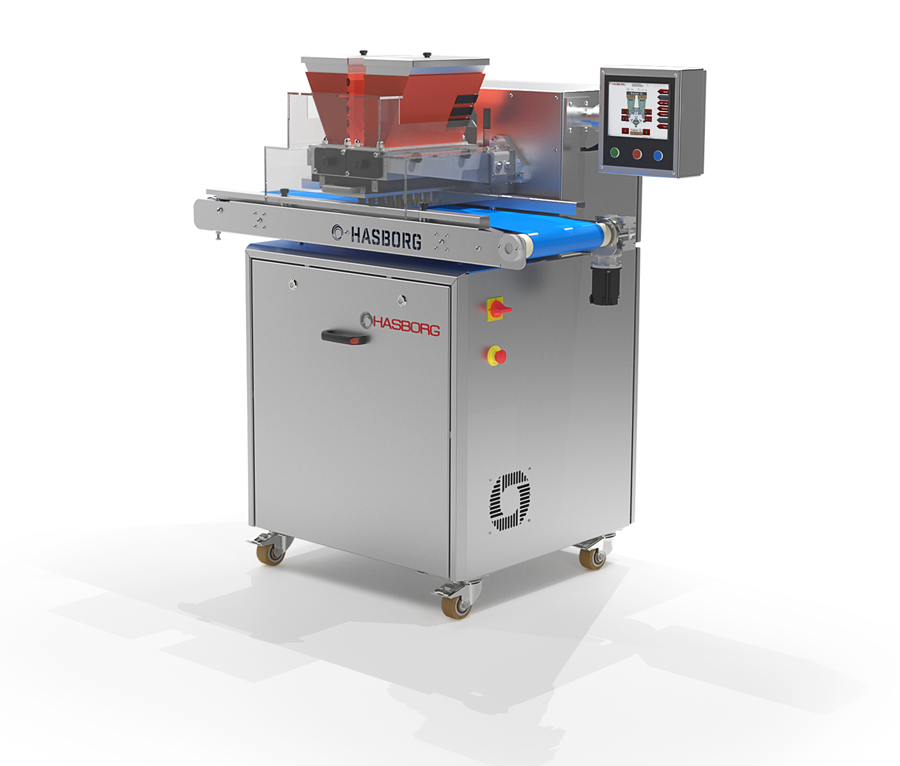

The compact machine on wheels can be used even in small factories producing real chocolate products.

The body of the machine is made of high-quality, acid-resistant stainless steel of the 304 group, all elements having direct contact with the chocolate and filling meet the required principles of safety for Food Contact Materials (FCMs)

The dosing head and the system of chocolate and filling feeding are made of hardened, anodized aluminum, which significantly increases the durability and reliability of the device.

The device has been designed in a way that maximally simplifies and shortens the cleaning and sanitation process after work.

Choco Max can work with 275 mm wide molds. The head in standard option is equipped with 8 dosing points. The hoppers for chocolate and filling are heated independently by heating mats

The device is controlled entirely from the 7” touch panel which is equipped with visual interface. This solution makes the operation of the machine simple and intuitive. The interface has a language selection function.

You can save your settings to external SD card. The machine can be connected to the WiFi network, which enables remote diagnostics and parameter correction.

Choco Max can be fully operated by only one person, which, combined with the high efficiency of the device, significantly reduces production costs and the price of the final product.