Description

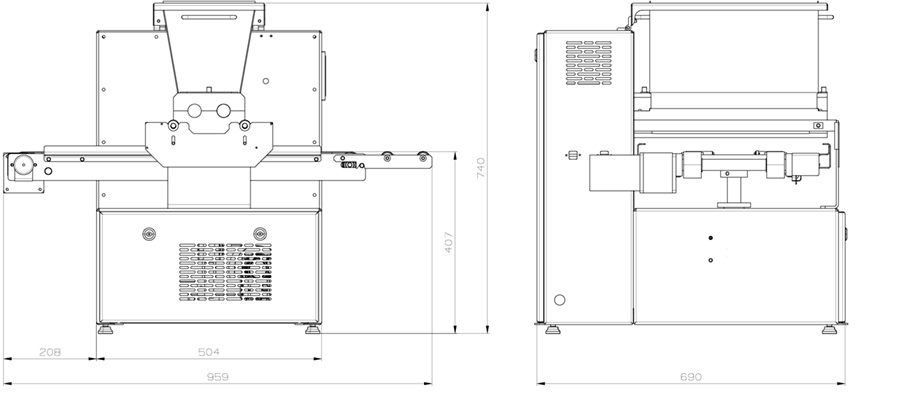

Technical informations

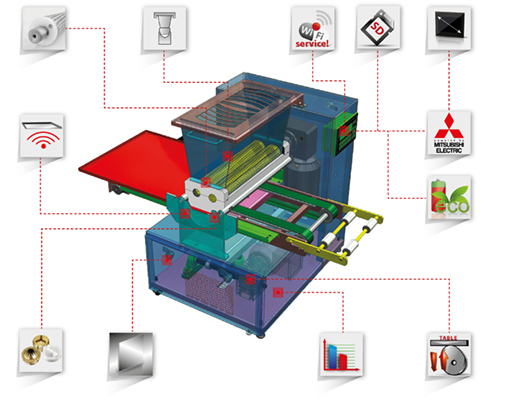

| Durable and stable frame made of stainless steel AISI 304. | Hermetic dough processing heads enable semi-liquid and hard dough processing. | ||

| Accurate table lifting system based on eccentrics that works lightly and provides failure-free operations. | IMU Unit – every machine can be connected to the Client‘s internet access point. Thanks to this, Hasborg service center can, if required, remotely connect to each machine for the service purposes, to upload software in case of new or upgraded program release, or to help with program set-up. | ||

| Ability to work with many different forming nozzles, both brass and plastic. | |

Powered by Mitsubishi Electric. | |

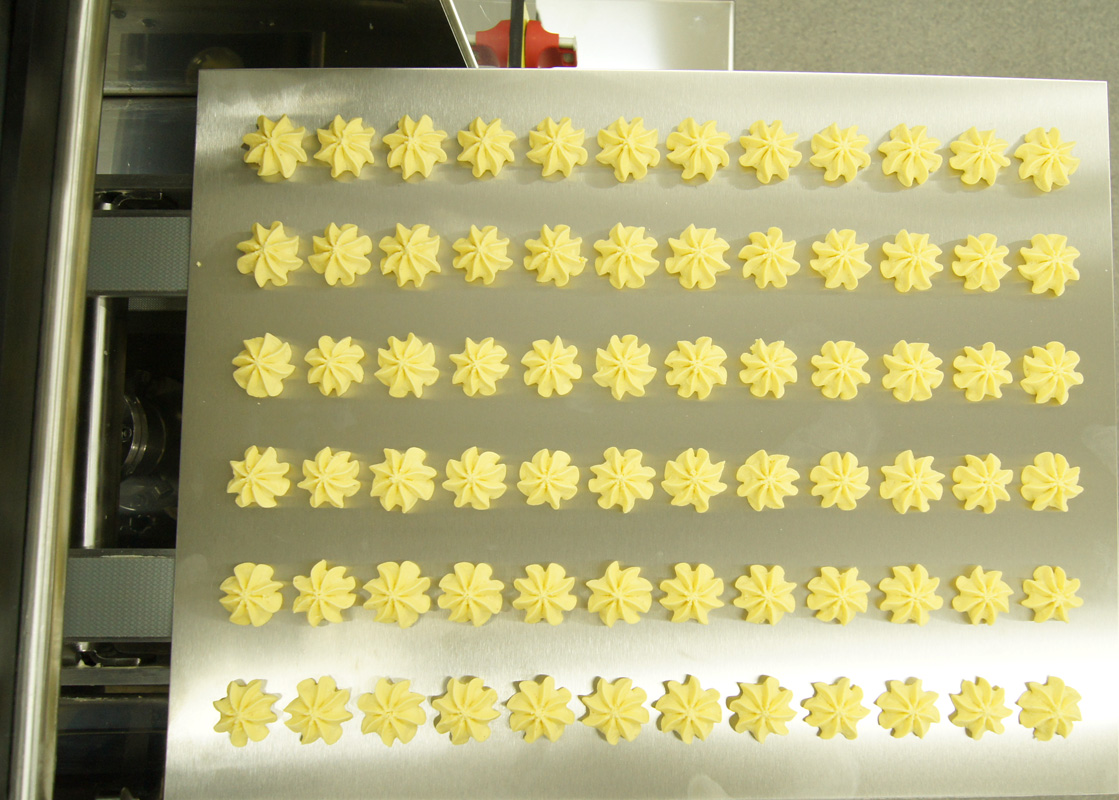

| Electronics and touch panel are simple and easy to use with multilingual menu. You can enter your own recipes and save them on the SD card. | High performance and repeatability of the final product. | ||

| Tray movement sensor and eletronic tray movement drive system. | High energy efficiency. | ||

| Stainless steel dough processing rolls with spiral cuts. |

Constructional and Functional Characteristic:

- Machine is adapted to work with many different types of dough: shortbread dough, sponge, steamed, marinque, muffins

- Possibility to use exchangeable forming nozzles with different patterns , made of plastic or brass

- Easy to clean and change equipment

- Solid and stabile casing made of stainless steel AISI 304

- Hermetic head made of high mechanical resistant material Poliacetal C POM-C, width 400mm

- 60mm in diameter Rolls made of stainless steel

- Precise table motion mechanism with camshaft

- PLC touchscreen operational panel with intuitive software that enables selection and precise control over required production.