- The double head made of one piece is designed in such a way that the dough, passing to the ends, does not hit flat surfaces, but travels all the way in a cone. Solid and stable construction made of stainless steel.

- Forming bars and dies with a special milled dough guide reduce the pressure in the head, thanks to which it passes more precisely to the forming tips.

- The quick and precise head lifting system does not require any lubrication, works lightly and without failures. The digital adjustment of the raising and lowering of the head allows the production of biscuits of different heights.

- Electronic system and PLC control panel are simple and user-friendly. The panel with a multilingual menu has the ability to enter your own recipes and save them on the SD card.

- Servo drives - a unique solution that increases the speed, life and precision of components.

- The system of the "module" for feeding the dough in the head was transferred from industrial lines.

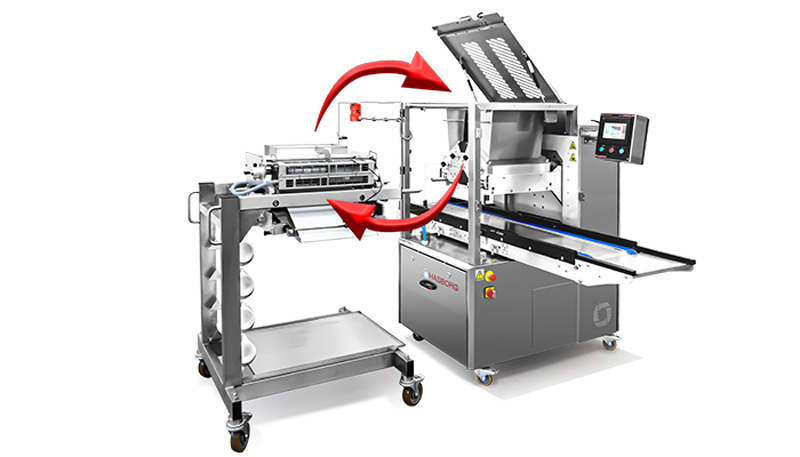

THIS DEVICE MCAN BE EQUIPPED WITH ADDITIONAL REPLACEABLE HEADS:

MAX-UNIVERSAL can be "armed" with six types of heads, which make it an even more universal machine and extend the possibilities of biscuit production with new patterns, shapes, etc.:

- Single hopper head - standard

- Single hopper head - gear pump

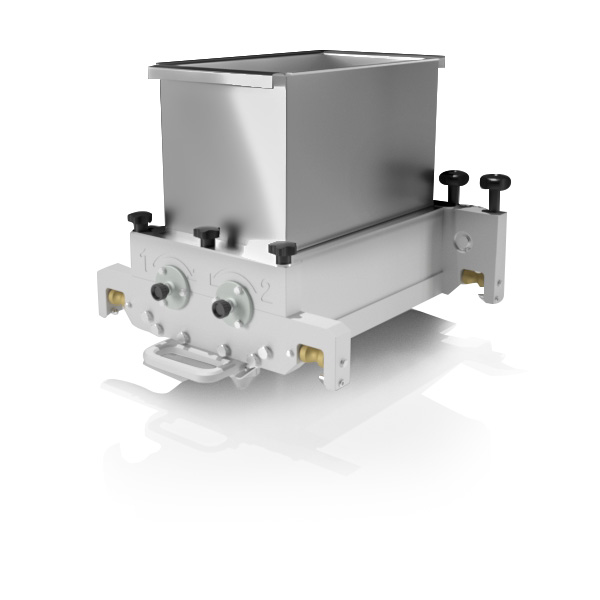

- Double hopper head 2 colors (2 hoppers standard)

- Double hopper head (1 hopper gear pump + 1 hopper standard)

- Forming head for muffins and other liquid masses

- Rotary moulder head

ADDITIONAL REPLACEABLE HEADS

MAX-UNIVERSAL can be "armed" with six types of forming heads, which make it an even more versatile machine and expand the possibilities of biscuit production with new patterns, shapes, etc.:

This device is equipped with one head as standard (we choose the basic configuration depending on what products we want to produce). The machine can be transformed into an increasingly universal pastry machine by purchasing additional heads for specific applications. We don't have to buy more machines, all you need is a compact Max Universal with the possibility of expanding it with new functions!

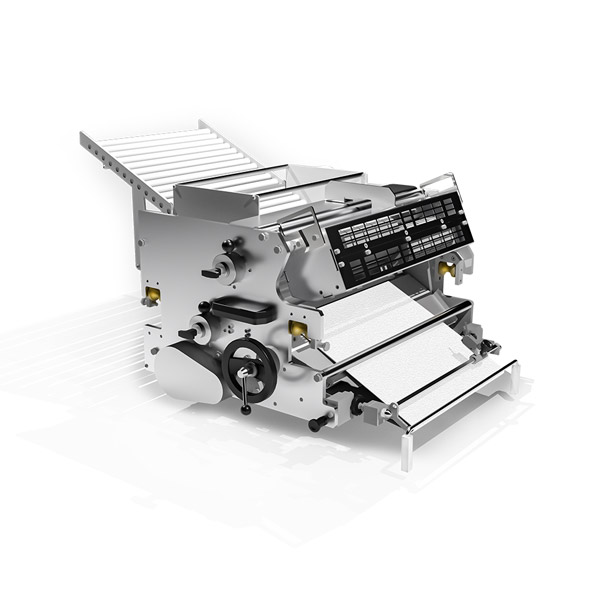

Rotary moulder head

this head can be placed in the machine in place of the standard head, thanks to which it becomes a roller machine. This head is designed for high-fat cookies extruded from the roller. We obtain shapes and textures determined by the type of roller used and the patterns that are applied to it.

MANY TYPES OF FORMING ROLLERS

The rollers are replaceable and their replacement is very simple. The conversion of a standard machine into a roller machine is a simple, quick and uncomplicated procedure. Then you get the opportunity to produce a completely new range of biscuits, which until now was associated with the need to purchase a completely different machine.

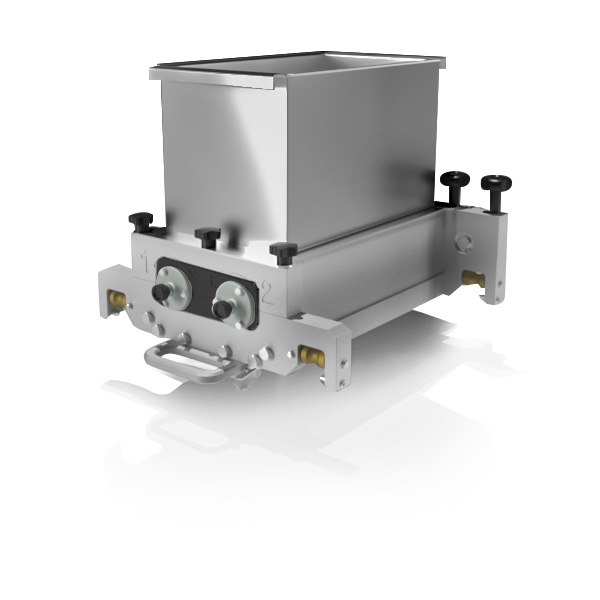

Standard machine head

With this head, we can get two-color and one-color cookies with a filling inside. Depending on the use of additional accessories and forming nozzles, we can obtain round, wrapped, low/high, oblong cookies, etc.

The head is suitable for shortcrust pastry, sponge cake, gingerbread, meringue, etc.

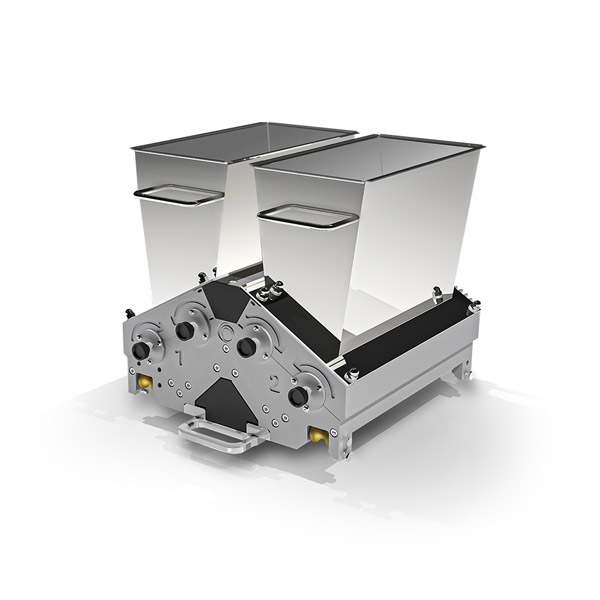

Double hopper head (1 hopper gear pump + 1 standard)

In this head, standard rollers for hard and semi-hard doughs are used in one part, and in the second hopper a solution based on a gear pump for liquid and semi-liquid fillings is used.

-5836.jpg)

Thanks to this solution, we can stuff cookies with liquid fillings in the form of creams, liqueurs, puddings, etc.

Head for muffins and liquid formulas

The construction of this head allows the production of muffins with additives, e.g. raisins, nuts, almonds, chocolate drops, etc.

The additives are mixed with the dough and the whole mass is fed into the tank. The piston feeding system used in the head allows you to dose muffins into molds without damaging its consistence.

At the same time, we obtain a very high reproducibility in terms of volume and weight of muffins in each cycle.

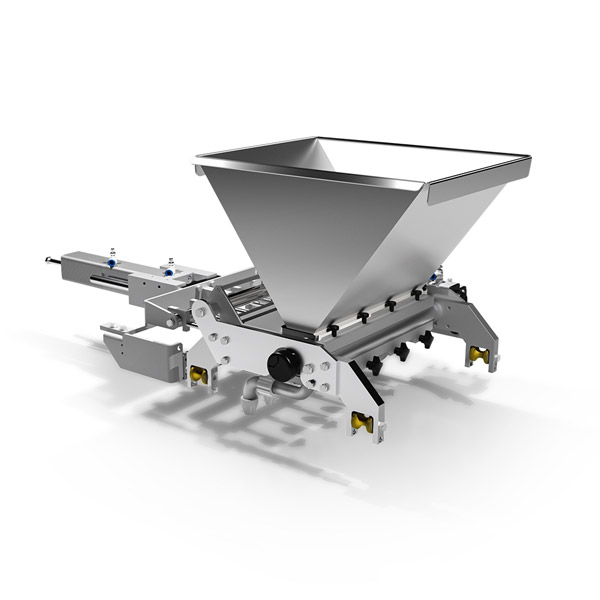

Single hopper head standard:

The head is designed for biscuits with a compact structure. Equipped with rollers with a large diameter of 115mm to precisely dispense the dough.

Single hopper head with gear pump

This head was designed to work with semi-liquid and liquid dough types.

ADDITIONAL EQUIPMENT OPTIONS

Forming slat for nozzles rotation

this machine in standard option is equipped with a forming slat for nozzles rotation with a set of six various forms

Guillotine

This ia a high capacity device for the production of long biscuits with filling inside

Wire-cut

this option is designed to produce biscuits that are cut by wire. Thanks to a variety of forms, you can obtain any shape of cookies with a selected thickness.

Shutter

this option allows the production of one and two color filled biscuits, using the mechanism of closing rings that cut off the dough coming out of the forming nozzles

Sponge tops

In this machine, we can use a special forming slat for forming biscuit tops. This slat has adjustment that regulates the thickness of the dough, thanks to which a layer of appropriate dimension is fed on the baking tray. This option can also be used to apply a layer of jam on the top of ready (baked) product.

Stamping unit

The machine can be equipped with a stamping device. Biscuits dispensed, for example, using a "shutter" can be flattened using a pneumatic stamper. Stamps can be smooth or with customized shapes giving the unique look of the biscuit

Technical parameters

Working width:

- 400