Description

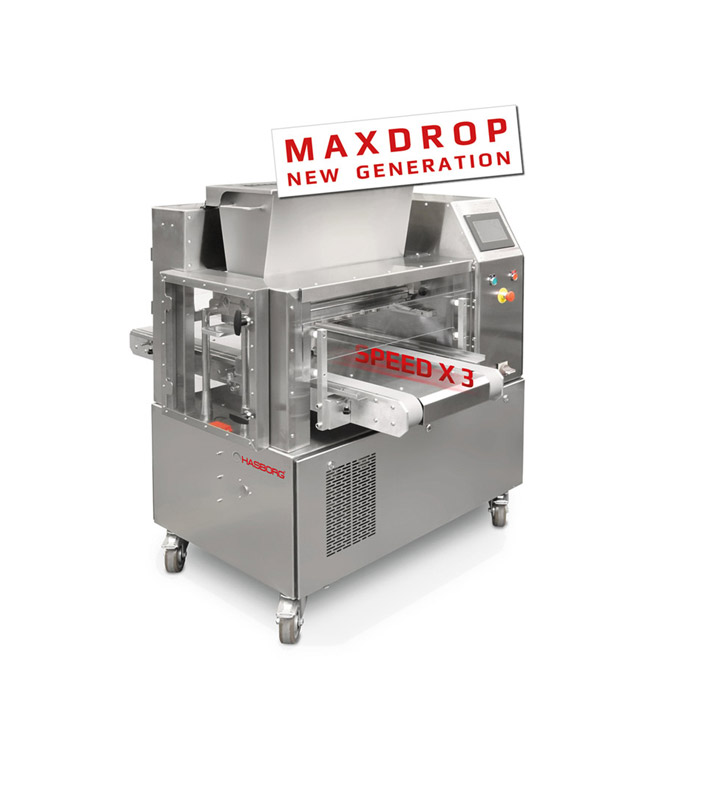

The components used in the device ensure trouble-free operation of the machine, and a simple operator panel allows you to control all parameters of the machine in an intuitive way. The machine is easy to operate, reliable and highly efficient.

- Hopper

- Control panel

- Belt cleaning system (easy to empty waste drawer)

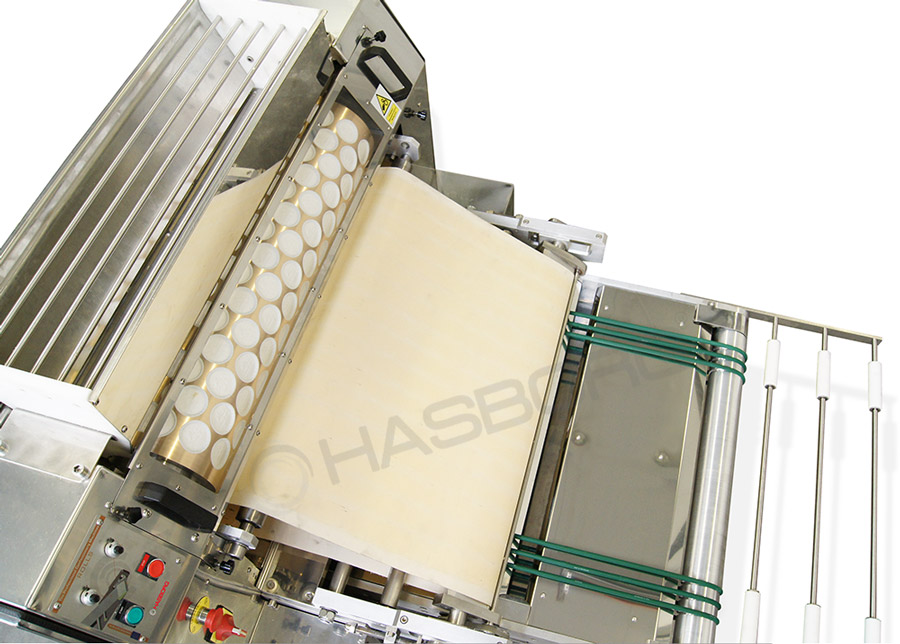

- Forming roll

- Conveyor belt

- Strong and durable design made of stainless steel

- Forming roll made of bronze, equipped with teflon forms with a selected pattern

- Easy and quick replacement of the forming roll

- Precise speed control of the forming roll

- Adjustable speed of the main table

- Tension adjustment of the extraction belt

- Adjustment of the "noses" of the extraction belt

- Belt cleaning system

- Easy to empty waste drawer

- Two independent drive motors: the forming roll, the extraction belt and the tray conveyor table

- Capacity up to 400 kg / h

- Work with baking trays with a working width of 600 mm and a length of 400mm or more

- 400V, 3-phase, 50Hz power supply

Presentation of squeezing "pretzels" cookies and their transport on baking trays