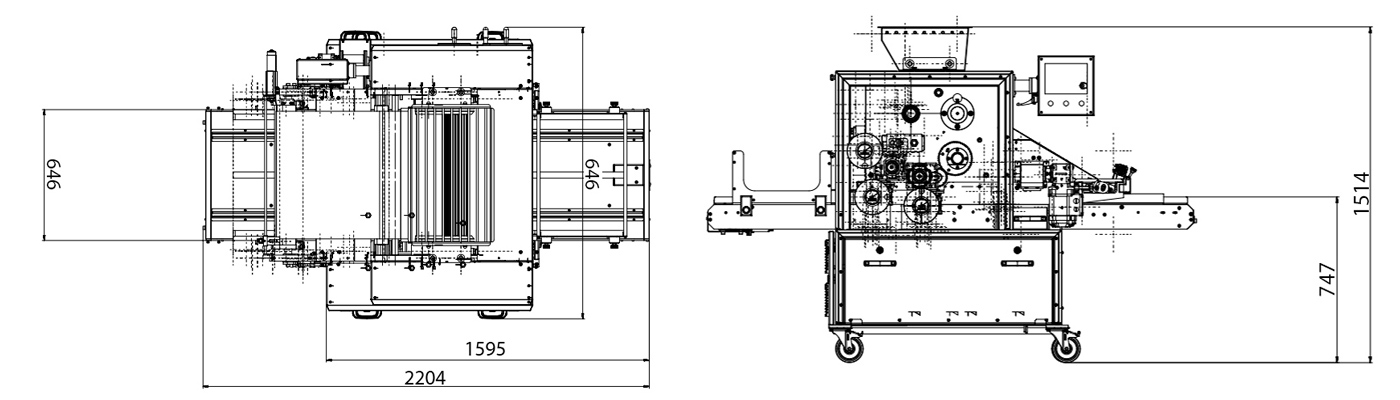

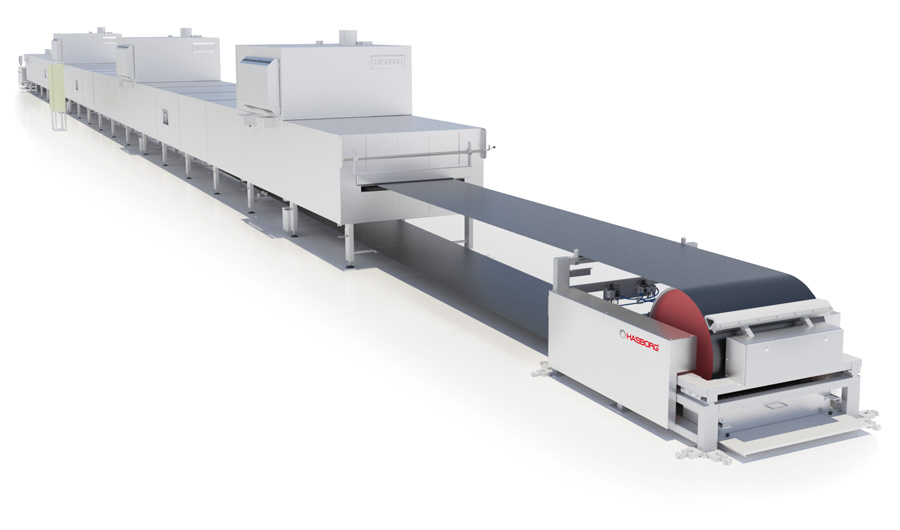

Rolls AP rotative moulder with automatic trays feeder

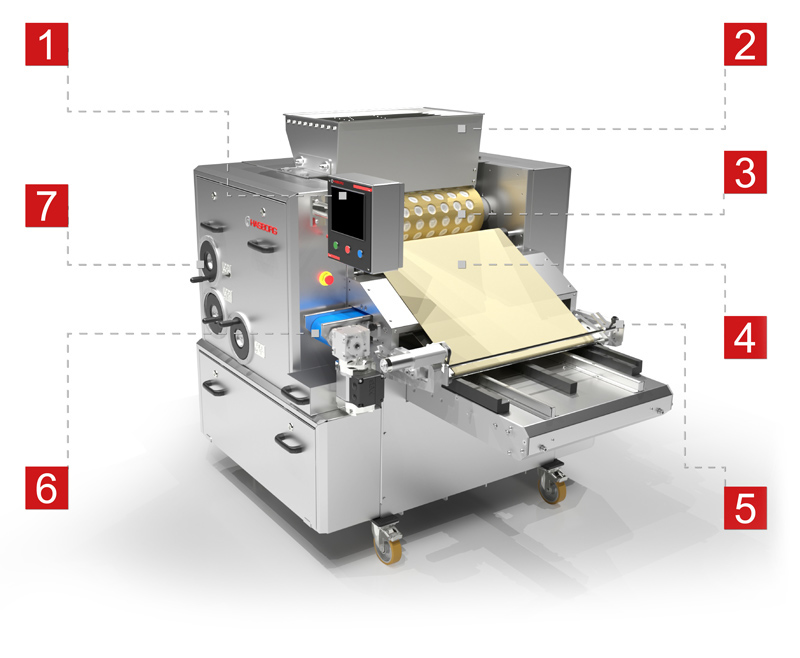

Machine description

The Rolls AP roller machine is equipped with a three-stage adjustment system that allows you to adjust the operating parameters to the type of dough processed. Each adjustment level has a knob with a counter, making it easy to control and change settings.

Changing the pattern of the biscuit is done by replacing the forming roller. It is also possible to place several different patterns of cookies of similar weight and shape on one roller, thanks to which we obtain a diverse end product during the production process.

The use of a large diameter roller has a positive effect on the process of forming biscuits and allows obtaining biscuits of large sizes.

After placing the dough in the tank, it is pressed into the forming roller, and then the formed cookies unstick on the tape, then going down to the baking tray.

The machine is equipped with an automatic trays feeder. Trays size 60x40 or 75x45 cm

The operation of the machine and its parameters are controlled through an intuitive LCD operator panel equipped with a multilingual menu wich allows settings to be saved on external SD media card. The control module is also equipped with WiFi connectivity, which enables remote diagnostics and configuration of machine parameters from the manufacturer's service center.

The components used ensure trouble-free operation and high efficiency.

- Control panel

- Dough feeding tank

- Forming roll

- Conveyor

- Trays detection sensor

- Automatic belt cleaning system (easy-to-empty waste drawer)

- Knobs with built-in counters - three independently adjustable drives

Automatic trays feeder

The used container allows you to place a dozen or so sheets in it. The trays are automatically fed to the machine and, after forming the cookies, are collected by the operator. Thanks to this automatic system - the machine can be operated by only one person, which significantly increases the efficiency and affects the economy of production.

Dough cutting knife regulation

First level of regulations

Adjustment of dough scraper knife angle

Second adjustment level

Adjustable rubber roller position

Third level of settings

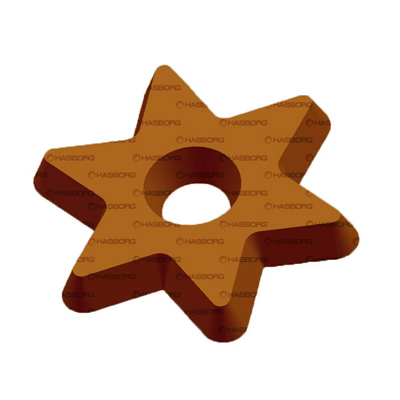

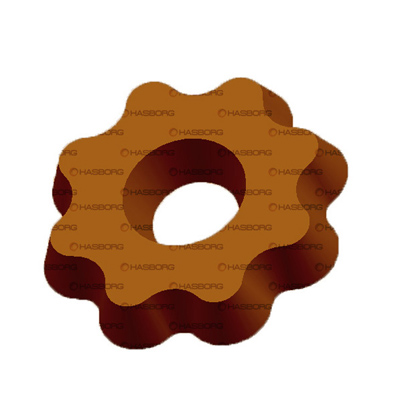

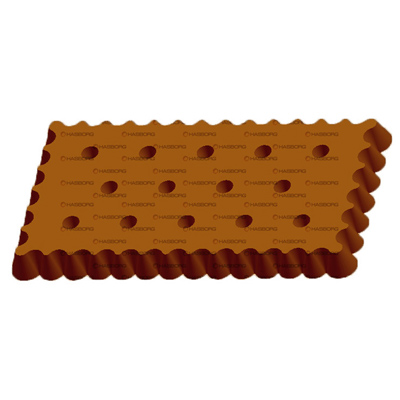

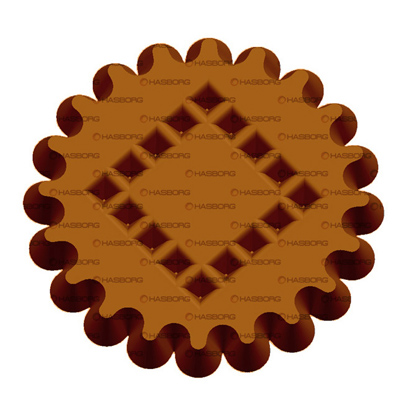

Cookie’s shape samples

Cookie’s samples